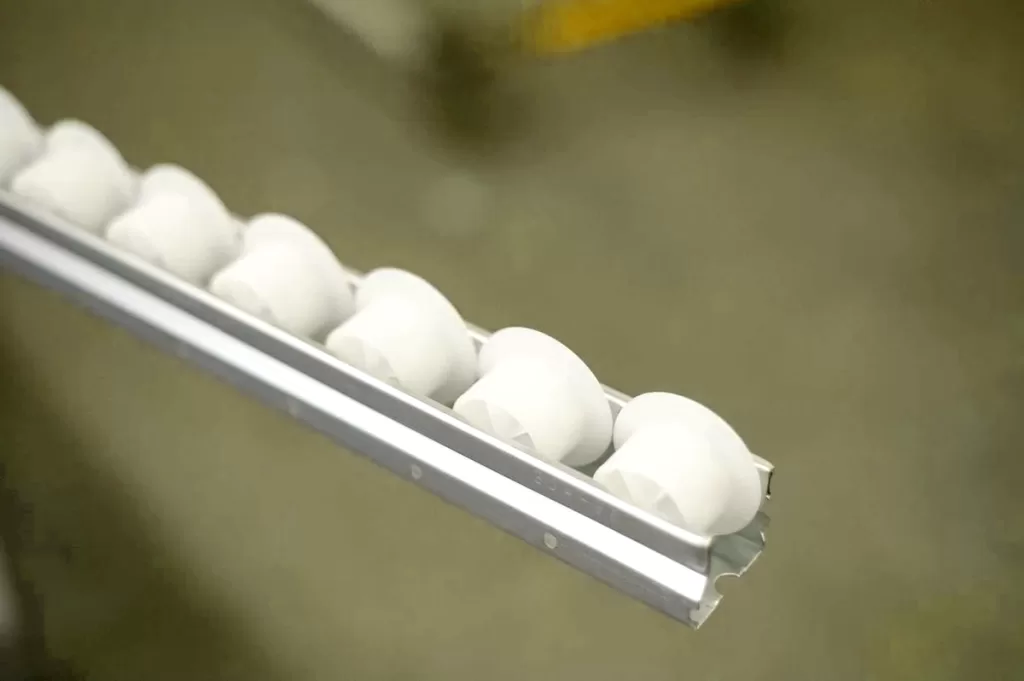

Roller Tracks

ideal solution for implementing efficient conveyor technology.

Benefits of Roller Tracks

Roller tracks facilitate the movement of SLC boxes, cartons, containers, or individual parts from one location to another using gravity. When two roller tracks are combined, they form a roller conveyor (without a drive system), which keeps the load carriers on track with the help of lateral guides.

Roller conveyors play a crucial role in many material handling systems, ensuring quick delivery of boxes and supporting the FIFO (First In, First Out) principle. From simple straight track systems for load carriers, transport containers, and cartons, to curved tracks and all-side rollers, to crate change systems, roller tracks provide the ideal solution for implementing efficient conveyor technology in your operations.

Features of roller tracks

- Load carriers are transported from the filling side to the removal side using a gradient, allowing transport containers or load carriers to move automatically and ensure reliable delivery.

- Roller tracks assist workers in moving heavy workpieces (over 20 kg) with ease by manually guiding them, such as between two workstations.

- Additionally, roller tracks are used for the efficient movement of containers or workpieces over longer distances. In these cases, the movement is typically powered by external energy sources, such as driven systems like conveyor belts, rather than relying on a gradient.

Types of roller tracks

Our roller track are available in various designs and with different roller diameters and can be combined with all our systems (steel pipe rack system, aluminum pipe rack system).

The roller tracks we manufacture have excellent running properties, smooth and low-noise passage over parts even on low slopes and high impact resistance. Their high stability ensures a long service life. They are available in various designs to meet different requirements.

A wide range of accessories, such as special fastening elements, lateral guides and stops, complete the product portfolio and provide an optimal connection for pipe rack systems.

Galvanized roller tracks are a durable and corrosion-resistant solution for material handling systems. The Tracks are coated with a layer of zinc through a galvanizing process, which helps protect the track from rust and wear, making them ideal for environments where moisture, chemicals, or other harsh conditions are present.

These roller tracks are widely used in warehouses, factories, and distribution centers for transporting goods like boxes, containers, and other load carriers. The galvanized coating ensures long-lasting performance and reduces the need for frequent maintenance or replacement, offering both efficiency and reliability in material handling operations.

Galvanized roller tracks are a durable and corrosion-resistant solution for material handling systems. The Tracks are coated with a layer of zinc through a galvanizing process, which helps protect the track from rust and wear, making them ideal for environments where moisture, chemicals, or other harsh conditions are present.

These roller tracks are widely used in warehouses, factories, and distribution centers for transporting goods like boxes, containers, and other load carriers. The galvanized coating ensures long-lasting performance and reduces the need for frequent maintenance or replacement, offering both efficiency and reliability in material handling operations.

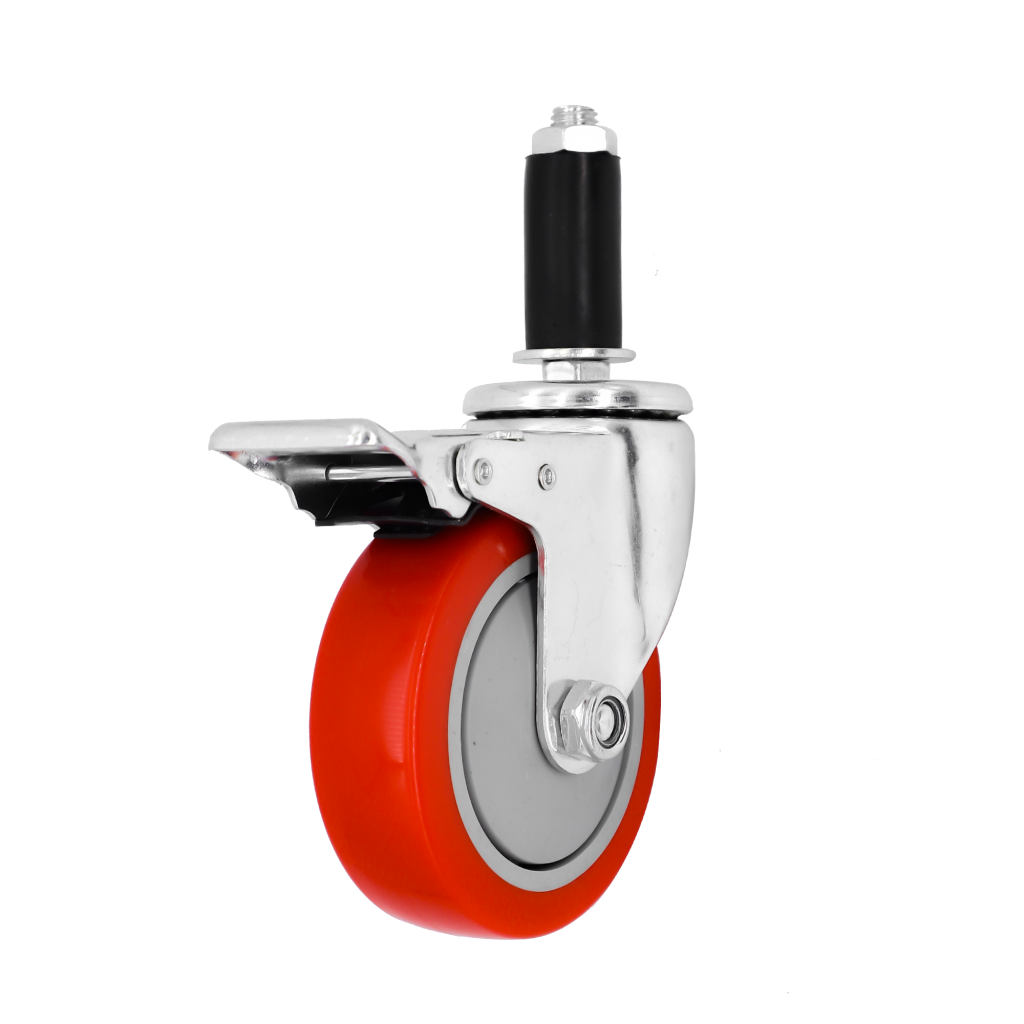

Add-on parts

Our roller tracks can be combined with pipe racking system steel and pipe joints to form a pipe racking system to ensure strength, flexibility and cost-effectiveness. Castors can be added to make the mobile racking flexible. This allows for a quick reaction if the layout of the production or warehouse changes.

Thanks to a wide range of modular accessories, various requirements in production and warehouses can be met.

Pipe Racking System

Pipe Joints

Castors